Over-Lock

Showing all 9 results

-

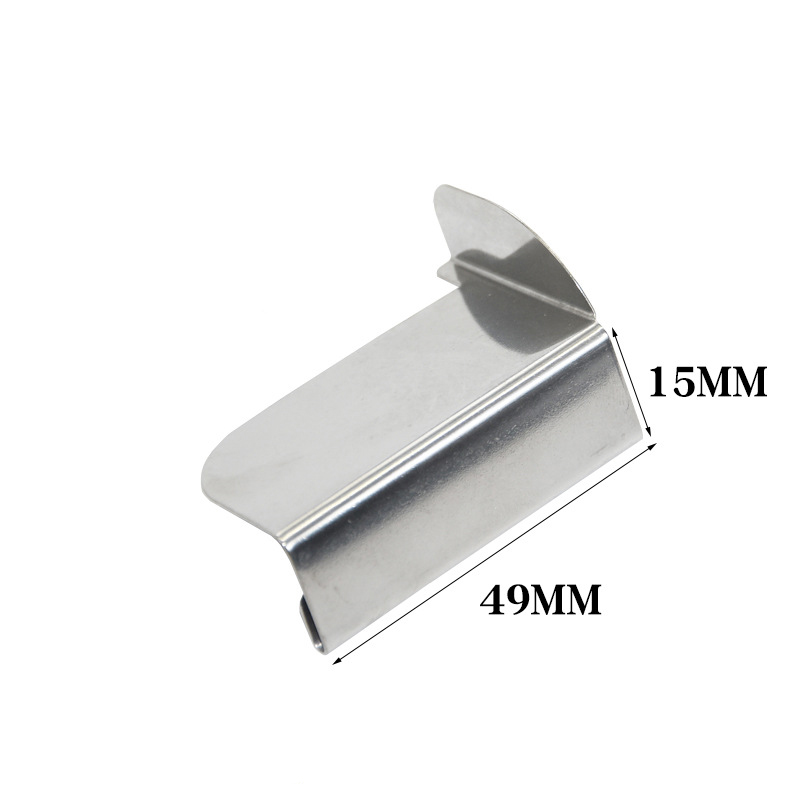

Feed Dog Assembly

Quick Viewhe Feed Dog Assembly is a spare part that is a critical component of a sewing machine’s feeding system. It is responsible for moving the fabric forward and guiding it through the machine during the stitching process.

The Feed Dog Assembly typically consists of several metal teeth that are designed to grip the fabric and move it through the machine at a consistent rate. It is typically adjustable, so that the user can control the speed and direction of the feed dogs depending on the type of fabric being used and the desired stitching outcome.

If the Feed Dog Assembly becomes worn or damaged, it can cause the fabric to be fed unevenly or not at all, resulting in poor-quality stitching or even needle breakage. In such cases, it may be necessary to replace the Feed Dog Assembly with a new one.

-

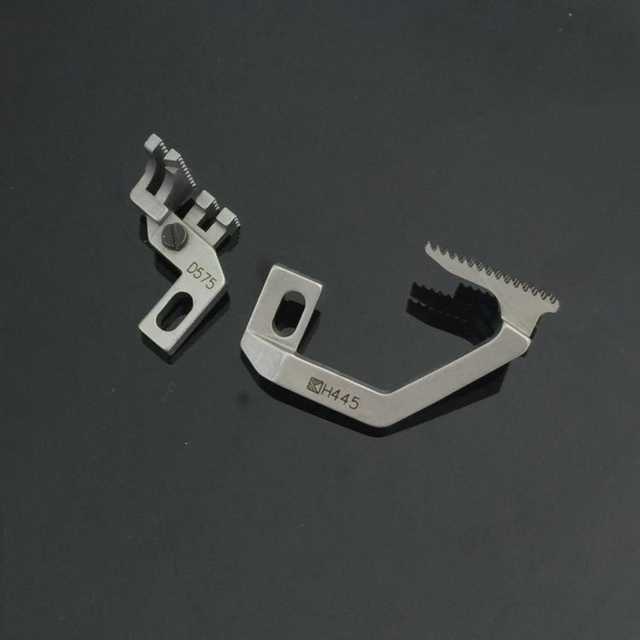

Fiber Guide

Quick ViewThe Fiber Guide is a spare part that is a critical component of a sewing machine’s thread delivery system. It is responsible for guiding the thread from the spool to the needle, ensuring that it is delivered smoothly and consistently during the stitching process.

The Fiber Guide typically consists of a small metal or plastic piece that is positioned near the spool of thread. It is designed to hold the thread in place and direct it towards the needle, reducing the risk of tangling or knotting.

If the Fiber Guide becomes worn or damaged, it can cause the thread to be delivered unevenly or not at all, resulting in poor-quality stitching or even thread breakage. In such cases, it may be necessary to replace the Fiber Guide with a new one.

-

Fiber Guide

Quick ViewThe Fiber Guide is a spare part that is a critical component of a sewing machine’s thread delivery system. It is responsible for guiding the thread from the spool to the needle, ensuring that it is delivered smoothly and consistently during the stitching process.

The Fiber Guide typically consists of a small metal or plastic piece that is positioned near the spool of thread. It is designed to hold the thread in place and direct it towards the needle, reducing the risk of tangling or knotting.

If the Fiber Guide becomes worn or damaged, it can cause the thread to be delivered unevenly or not at all, resulting in poor-quality stitching or even thread breakage. In such cases, it may be necessary to replace the Fiber Guide with a new one.

-

Needle Plate OL

Quick ViewThe Needle Plate OL is a spare part that is a critical component of a sewing machine’s stitching mechanism. It is responsible for guiding the needle and thread through the fabric during the stitching process.

The Needle Plate OL typically consists of a metal plate that is positioned beneath the fabric being stitched. It contains a small hole that allows the needle to pass through and make contact with the fabric. The Needle Plate OL also typically contains a series of markings and guides that help the user to maintain a straight and even stitching line.

If the Needle Plate OL becomes worn or damaged, it can cause the needle to strike the plate, resulting in poor-quality stitching, needle breakage, or even damage to the machine itself. In such cases, it may be necessary to replace the Needle Plate OL with a new one.

-

Overlock Stitch Sewing Machine DS-S90D

Quick ViewDirect Drive Computerized All Auto-overlock Sewing MachineFEATURES:- With the wring function, multi-segment of fixed length seam function, loose line function, soft start function, and external electric eye sensor.

- Auto cutting, fixed length gap trigger, auto air intake, manual segment switch, and manual air intake switch.

- Auto presser-foot lifting, before the cutting and after the cutting, etc.

- Solve the waste material are in the front cover after cutter to cloth, and excessive accumulation effect problem using for the machine.

-

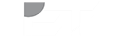

Pressure Foot Assembly

Quick ViewThe Pressure Foot Assembly is a spare part that is a critical component of a sewing machine’s feeding system. It is responsible for holding the fabric in place and controlling the amount of pressure applied to it during the stitching process.

The Pressure Foot Assembly typically consists of a metal or plastic foot that is positioned above the fabric being stitched. It is designed to hold the fabric in place and guide it through the machine at a consistent rate. The Pressure Foot Assembly also typically contains a mechanism for adjusting the amount of pressure applied to the fabric, allowing the user to control the stitching tension.

If the Pressure Foot Assembly becomes worn or damaged, it can cause the fabric to be fed unevenly or not at all, resulting in poor-quality stitching or even needle breakage. In such cases, it may be necessary to replace the Pressure Foot Assembly with a new one.

-

Siruba 747 Looper Upper and Lower

Quick ViewThe Siruba 747 Looper Upper and Lower are spare parts that are critical components of a serger or overlock sewing machine’s loopers mechanism. They are responsible for creating the loops that encase the raw edges of fabric and prevent them from fraying.

The Looper Upper and Lower typically consist of two metal pieces that are positioned above and below the fabric being stitched. They work in tandem to form the loop and secure it in place. The Looper Upper and Lower move in a synchronized motion, threading the thread through the fabric and forming the stitch.

If the Looper Upper and Lower become worn or damaged, they can cause the machine to produce poor-quality stitching or even break the needles. In such cases, it may be necessary to replace the Looper Upper and Lower with new ones.

-

Siruba 747-4-4 Needle

Quick ViewThe Siruba 747-4-4 Needle Holder is a spare part that is a critical component of a serger or overlock sewing machine’s needle mechanism. It is responsible for holding the needles in place and controlling their movement during the stitching process.

The Needle Holder typically consists of a metal or plastic bracket that holds the needles securely in place. It is designed to guide the needles through the fabric at a consistent rate and prevent them from bending or breaking. The Needle Holder also typically contains a mechanism for adjusting the needle position, allowing the user to control the stitching tension.

If the Needle Holder becomes worn or damaged, it can cause the needles to be misaligned or fall out of the machine, resulting in poor-quality stitching or even machine damage. In such cases, it may be necessary to replace the Needle Holder with a new one.

-

Siruba 747-4-4 Needle Holder

Quick ViewThe Siruba 747-4-4 Needle Holder is a spare part that is a critical component of a serger or overlock sewing machine’s needle mechanism. It is responsible for holding the needles in place and controlling their movement during the stitching process.

The Needle Holder typically consists of a metal or plastic bracket that holds the needles securely in place. It is designed to guide the needles through the fabric at a consistent rate and prevent them from bending or breaking. The Needle Holder also typically contains a mechanism for adjusting the needle position, allowing the user to control the stitching tension.

If the Needle Holder becomes worn or damaged, it can cause the needles to be misaligned or fall out of the machine, resulting in poor-quality stitching or even machine damage. In such cases, it may be necessary to replace the Needle Holder with a new one.