Lock Stitch

Showing all 17 results

-

Bobbin Winder

Quick ViewThe Bobbin Winder Assembly is a spare part that is a critical component of a sewing machine’s bobbin winding system. It is responsible for winding thread onto the bobbin, which is used to create the lower thread of a sewing project.

The Bobbin Winder Assembly typically consists of a bobbin winder spindle, a bobbin winding mechanism, and a motor or hand crank to power the assembly. When engaged, it winds thread from the upper thread spool onto the bobbin, creating an even and consistent layer of thread.

If the Bobbin Winder Assembly becomes worn or damaged, it can cause the bobbin winding process to become uneven or unstable, resulting in poorly wound bobbins that can cause thread tension issues or even thread breakage. In such cases, it may be necessary to replace the Bobbin Winder Assembly with a new one.

-

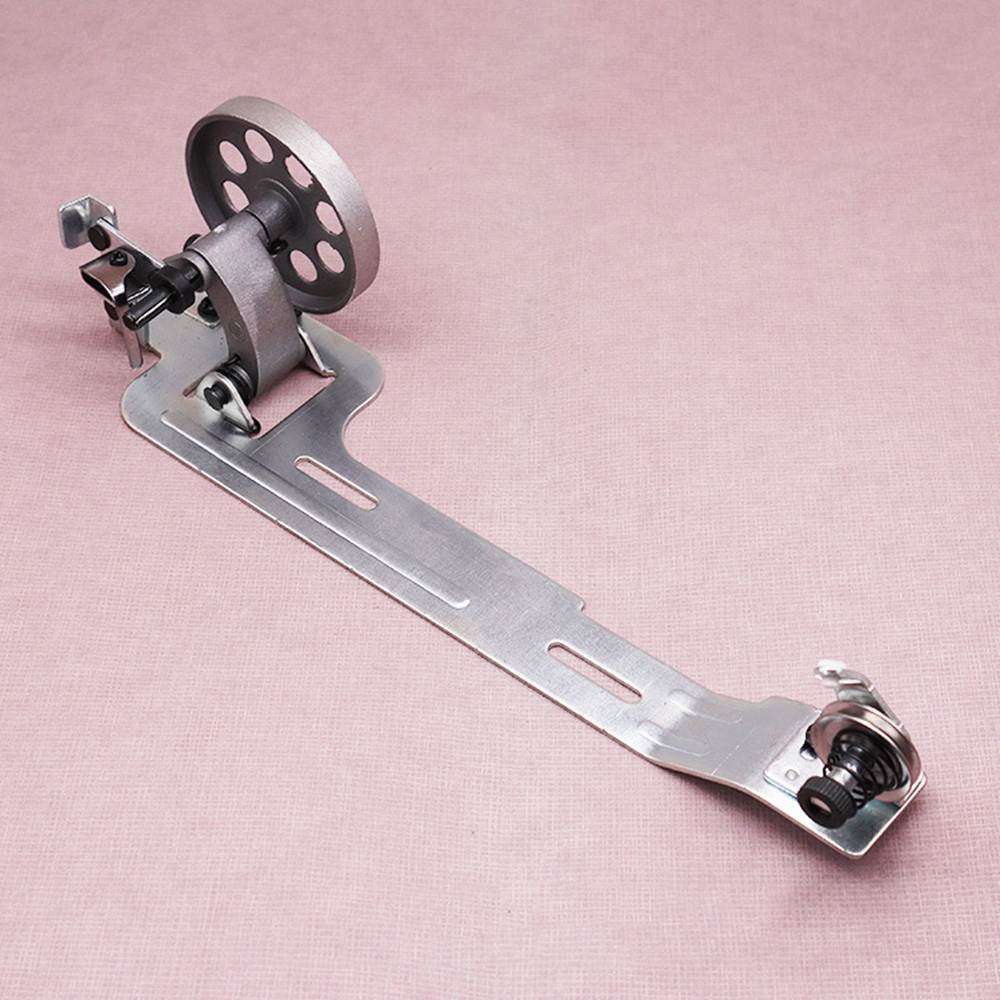

Bobbin Winder Assembly

Quick ViewThe Bobbin Winder Assembly is a spare part that is a critical component of a sewing machine’s bobbin winding system. It is responsible for winding thread onto the bobbin, which is used to create the lower thread of a sewing project.

The Bobbin Winder Assembly typically consists of a bobbin winder spindle, a bobbin winding mechanism, and a motor or hand crank to power the assembly. When engaged, it winds thread from the upper thread spool onto the bobbin, creating an even and consistent layer of thread.

If the Bobbin Winder Assembly becomes worn or damaged, it can cause the bobbin winding process to become uneven or unstable, resulting in poorly wound bobbins that can cause thread tension issues or even thread breakage. In such cases, it may be necessary to replace the Bobbin Winder Assembly with a new one.

-

Bobbin Winder Assembly

Quick ViewThe Bobbin Winder Assembly is a spare part that is a critical component of a sewing machine’s bobbin winding system. It is responsible for winding thread onto the bobbin, which is used to create the lower thread of a sewing project.

The Bobbin Winder Assembly typically consists of a bobbin winder spindle, a bobbin winding mechanism, and a motor or hand crank to power the assembly. When engaged, it winds thread from the upper thread spool onto the bobbin, creating an even and consistent layer of thread.

If the Bobbin Winder Assembly becomes worn or damaged, it can cause the bobbin winding process to become uneven or unstable, resulting in poorly wound bobbins that can cause thread tension issues or even thread breakage. In such cases, it may be necessary to replace the Bobbin Winder Assembly with a new one.

-

Bobbins

Quick ViewBobbins are small spools of thread that are placed in the lower part of the sewing machine. They hold the thread that is used to create the bottom stitches of the fabric.

-

Bobbins

Quick ViewBobbins are small spools of thread that are placed in the lower part of the sewing machine. They hold the thread that is used to create the bottom stitches of the fabric.

-

Folder

Quick ViewFolder spare parts are important for achieving high-quality and efficient production in sewing operations. By using the appropriate folder spare parts and ensuring that they are properly maintained and replaced as needed, sewing professionals can create precise and consistent folds in a variety of fabrics, saving time and improving the quality of their finished products.

-

Folder

Quick ViewFolder spare parts are important for achieving high-quality and efficient production in sewing operations. By using the appropriate folder spare parts and ensuring that they are properly maintained and replaced as needed, sewing professionals can create precise and consistent folds in a variety of fabrics, saving time and improving the quality of their finished products.

-

Folder Assembly

Quick ViewFolder spare parts are components that are used with a sewing machine to create precise and consistent folds in fabric. These parts are typically used in industrial sewing machines and are commonly used in the production of clothing, upholstery, and other textile products.

Some common folder spare parts include the folder attachment, which is used to guide the fabric as it is folded, and the folding blade, which is responsible for creating the fold. Other folder spare parts may include the folder foot, folder guide, and folder plate, all of which work together to ensure that the fabric is folded accurately and consistently.

Folder spare parts are important for achieving high-quality and efficient production in sewing operations. By using the appropriate folder spare parts and ensuring that they are properly maintained and replaced as needed, sewing professionals can create precise and consistent folds in a variety of fabrics, saving time and improving the quality of their finished products.

-

Folder Assembly

Quick ViewFolder spare parts are components that are used with a sewing machine to create precise and consistent folds in fabric. These parts are typically used in industrial sewing machines and are commonly used in the production of clothing, upholstery, and other textile products.

Some common folder spare parts include the folder attachment, which is used to guide the fabric as it is folded, and the folding blade, which is responsible for creating the fold. Other folder spare parts may include the folder foot, folder guide, and folder plate, all of which work together to ensure that the fabric is folded accurately and consistently.

Folder spare parts are important for achieving high-quality and efficient production in sewing operations. By using the appropriate folder spare parts and ensuring that they are properly maintained and replaced as needed, sewing professionals can create precise and consistent folds in a variety of fabrics, saving time and improving the quality of their finished products.

-

Lockstitch Sewing Machine DS-6690D-560-820

Quick ViewLong arm high-speed single needle direct-drive with built-in panel lockstitch sewing machineFEATURES:- Big operating space, more conducive to the large object sewing work.

- Roller presser foot, steel base, and polyurethane binding cloth feeding teeth can meet a variety of sewing.

- Tangent stability, A rotating type cutting device for any type of suture can be a stable tangent.

- Foot pressure digital regulation, setting is convenient and accurate

-

Presser Foot LS

Quick ViewThe Presser Foot LS is a spare part that is a critical component of a sewing machine’s presser foot system. It is responsible for holding the fabric in place and feeding it through the machine during the stitching process.

The Presser Foot LS is typically made of metal and is designed to be durable and long-lasting. It is typically adjustable, so that it can be positioned at the correct distance from the needle to ensure that the fabric is held securely and fed smoothly through the machine.

If the Presser Foot LS becomes worn or damaged, it can cause the fabric to be held unevenly or not at all, resulting in poor-quality stitching or even needle breakage. In such cases, it may be necessary to replace the Presser Foot LS with a new one.

Replacing the Presser Foot LS is typically a straightforward process, but it requires some technical skill and should only be attempted by experienced sewists. It is important to select the correct Presser Foot LS that matches the make and model of the sewing machine, as well as to properly calibrate the presser foot system after installation to ensure that it is working correctly. Proper maintenance and replacement of the Presser Foot LS is essential for achieving high-quality stitching and prolonging the lifespan of a sewing machine.

-

Presser-Foot Assembly

Quick ViewThe presser-foot assembly is an essential part of a sewing machine that holds the fabric in place and ensures that it is fed smoothly through the machine. This assembly is made up of several spare parts that work together to create a firm grip on the fabric, allowing for precise stitching and preventing the fabric from slipping or bunching up.

-

Tension Post Dnl

Quick ViewThe tension post Dnl is a spare part that is a critical component of a sewing machine’s tension system. It is responsible for controlling the tension of the upper thread, ensuring that it feeds smoothly through the machine and forms high-quality stitches.

The tension post Dnl is typically made of metal and is designed to be durable and long-lasting. It is located near the top of the sewing machine and is connected to the tension discs and tension regulator.

When the tension post Dnl is properly adjusted, it maintains the correct level of tension on the upper thread, allowing it to feed smoothly through the machine without getting tangled or breaking. However, if the tension post Dnl becomes worn or damaged, it can cause the tension to become uneven or unstable, resulting in poor-quality stitching or even thread breakage.

-

Third Tension Asf

Quick ViewThe third tension asf is typically located on the bobbin case or shuttle hook assembly and is designed to ensure that the lower thread is fed smoothly through the machine and forms high-quality stitches. It works in conjunction with the upper tension system, which controls the tension of the upper thread.

When the third tension asf is properly adjusted, it maintains the correct level of tension on the lower thread, allowing it to feed smoothly through the machine and create even and consistent stitches. However, if the third tension asf becomes worn or damaged, it can cause the tension to become uneven or unstable, resulting in poor-quality stitching or even thread breakage.

Replacing the third tension asf with a new one is a straightforward process and can help to restore optimal performance to a sewing machine’s tension system. It is important to select the correct third tension asf that matches the make and model of the sewing machine, as well as to properly calibrate the tension system after installation to ensure that it is working correctly.

-

Thread Kinfe

Quick ViewThe Thread Knife is a spare part that is found on some sewing machines and is used to cut the thread after a seam has been sewn. It is typically located near the needle and works by sliding over the edge of the fabric to trim the thread.

The Thread Knife is typically made of metal and is designed to be durable and long-lasting. It is usually adjustable, so that it can be positioned at the correct distance from the needle to ensure that the thread is cut cleanly and at the right length.

If the Thread Knife becomes dull or damaged, it can result in ragged or uneven thread ends, which can be unsightly and may even cause the thread to become tangled or break. In such cases, it may be necessary to replace the Thread Knife with a new one.

-

Thread Kinfe

Quick ViewThe Thread Knife is a spare part that is found on some sewing machines and is used to cut the thread after a seam has been sewn. It is typically located near the needle and works by sliding over the edge of the fabric to trim the thread.

The Thread Knife is typically made of metal and is designed to be durable and long-lasting. It is usually adjustable, so that it can be positioned at the correct distance from the needle to ensure that the thread is cut cleanly and at the right length.

If the Thread Knife becomes dull or damaged, it can result in ragged or uneven thread ends, which can be unsightly and may even cause the thread to become tangled or break. In such cases, it may be necessary to replace the Thread Knife with a new one.

-

Thread Tension Assembly For Juki Sewing Machine

Quick ViewMaterial: Made With Durable Steel and High-quality Metal

Brand: Imported

Complete Set Included

Tension Disk:

Tension Spring

Tension Adjustment Dial/Knob

Tension Release Lever