Sewing

-

Looper DFL

The Looper DFL is a spare part for a sewing machine that is a critical component of the machine’s overlock or serger mechanism. It is responsible for creating the loop that interlocks with the needle thread to create a secure stitch.

The Looper typically consists of a metal or plastic component that is positioned next to the needles and moves in synchronization with them. It is designed to thread the needle thread through the fabric and then create a loop that is caught by the looper thread. The two threads are then interlocked to create a secure stitch.

If the Looper becomes worn or damaged, it can cause the machine to produce poor-quality or incomplete stitches. In such cases, it may be necessary to replace the Looper with a new one.

-

Looper DFL

The Looper DFL is a spare part for a sewing machine that is a critical component of the machine’s overlock or serger mechanism. It is responsible for creating the loop that interlocks with the needle thread to create a secure stitch.

The Looper typically consists of a metal or plastic component that is positioned next to the needles and moves in synchronization with them. It is designed to thread the needle thread through the fabric and then create a loop that is caught by the looper thread. The two threads are then interlocked to create a secure stitch.

If the Looper becomes worn or damaged, it can cause the machine to produce poor-quality or incomplete stitches. In such cases, it may be necessary to replace the Looper with a new one.

-

Looper DFL

The Looper DFL is a spare part for a sewing machine that is a critical component of the machine’s overlock or serger mechanism. It is responsible for creating the loop that interlocks with the needle thread to create a secure stitch.

The Looper typically consists of a metal or plastic component that is positioned next to the needles and moves in synchronization with them. It is designed to thread the needle thread through the fabric and then create a loop that is caught by the looper thread. The two threads are then interlocked to create a secure stitch.

If the Looper becomes worn or damaged, it can cause the machine to produce poor-quality or incomplete stitches. In such cases, it may be necessary to replace the Looper with a new one.

-

Looper DFL

The Looper DFL is a spare part for a sewing machine that is a critical component of the machine’s overlock or serger mechanism. It is responsible for creating the loop that interlocks with the needle thread to create a secure stitch.

The Looper typically consists of a metal or plastic component that is positioned next to the needles and moves in synchronization with them. It is designed to thread the needle thread through the fabric and then create a loop that is caught by the looper thread. The two threads are then interlocked to create a secure stitch.

If the Looper becomes worn or damaged, it can cause the machine to produce poor-quality or incomplete stitches. In such cases, it may be necessary to replace the Looper with a new one.

-

Looper DFL

The Looper DFL is a spare part for a sewing machine that is a critical component of the machine’s overlock or serger mechanism. It is responsible for creating the loop that interlocks with the needle thread to create a secure stitch.

The Looper typically consists of a metal or plastic component that is positioned next to the needles and moves in synchronization with them. It is designed to thread the needle thread through the fabric and then create a loop that is caught by the looper thread. The two threads are then interlocked to create a secure stitch.

If the Looper becomes worn or damaged, it can cause the machine to produce poor-quality or incomplete stitches. In such cases, it may be necessary to replace the Looper with a new one.

-

Looper DFL

The Looper DFL is a spare part for a sewing machine that is a critical component of the machine’s overlock or serger mechanism. It is responsible for creating the loop that interlocks with the needle thread to create a secure stitch.

The Looper typically consists of a metal or plastic component that is positioned next to the needles and moves in synchronization with them. It is designed to thread the needle thread through the fabric and then create a loop that is caught by the looper thread. The two threads are then interlocked to create a secure stitch.

If the Looper becomes worn or damaged, it can cause the machine to produce poor-quality or incomplete stitches. In such cases, it may be necessary to replace the Looper with a new one.

-

Looper DFL

The Looper DFL is a spare part for a sewing machine that is a critical component of the machine’s overlock or serger mechanism. It is responsible for creating the loop that interlocks with the needle thread to create a secure stitch.

The Looper typically consists of a metal or plastic component that is positioned next to the needles and moves in synchronization with them. It is designed to thread the needle thread through the fabric and then create a loop that is caught by the looper thread. The two threads are then interlocked to create a secure stitch.

If the Looper becomes worn or damaged, it can cause the machine to produce poor-quality or incomplete stitches. In such cases, it may be necessary to replace the Looper with a new one.

-

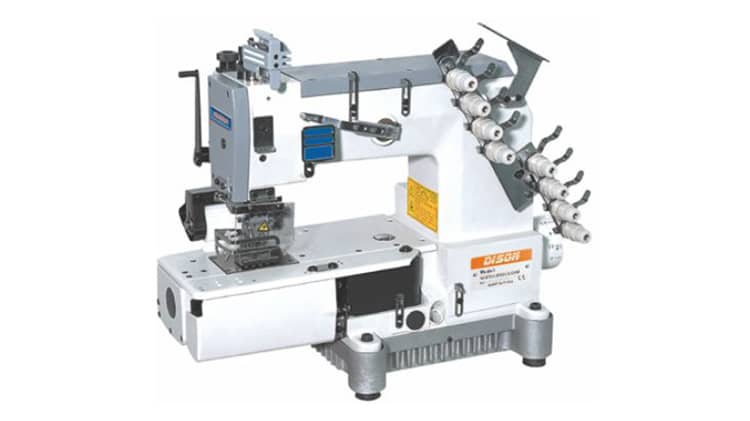

Multi-Needle Sewing Machine DS008-04064P

Multi-needle cylinder bed double chain stitch machineFEATURES:- Cylinder bed automatic oil.

- Back and forth looper driving mechanism.

- Needle inquiry or gaps can be changed according to the desired sewing pattern.

-

Needle Plate OL

The Needle Plate OL is a spare part that is a critical component of a sewing machine’s stitching mechanism. It is responsible for guiding the needle and thread through the fabric during the stitching process.

The Needle Plate OL typically consists of a metal plate that is positioned beneath the fabric being stitched. It contains a small hole that allows the needle to pass through and make contact with the fabric. The Needle Plate OL also typically contains a series of markings and guides that help the user to maintain a straight and even stitching line.

If the Needle Plate OL becomes worn or damaged, it can cause the needle to strike the plate, resulting in poor-quality stitching, needle breakage, or even damage to the machine itself. In such cases, it may be necessary to replace the Needle Plate OL with a new one.

-

Overlock Stitch Sewing Machine DS-S90D

Direct Drive Computerized All Auto-overlock Sewing MachineFEATURES:- With the wring function, multi-segment of fixed length seam function, loose line function, soft start function, and external electric eye sensor.

- Auto cutting, fixed length gap trigger, auto air intake, manual segment switch, and manual air intake switch.

- Auto presser-foot lifting, before the cutting and after the cutting, etc.

- Solve the waste material are in the front cover after cutter to cloth, and excessive accumulation effect problem using for the machine.

-

Presser Foot LS

The Presser Foot LS is a spare part that is a critical component of a sewing machine’s presser foot system. It is responsible for holding the fabric in place and feeding it through the machine during the stitching process.

The Presser Foot LS is typically made of metal and is designed to be durable and long-lasting. It is typically adjustable, so that it can be positioned at the correct distance from the needle to ensure that the fabric is held securely and fed smoothly through the machine.

If the Presser Foot LS becomes worn or damaged, it can cause the fabric to be held unevenly or not at all, resulting in poor-quality stitching or even needle breakage. In such cases, it may be necessary to replace the Presser Foot LS with a new one.

Replacing the Presser Foot LS is typically a straightforward process, but it requires some technical skill and should only be attempted by experienced sewists. It is important to select the correct Presser Foot LS that matches the make and model of the sewing machine, as well as to properly calibrate the presser foot system after installation to ensure that it is working correctly. Proper maintenance and replacement of the Presser Foot LS is essential for achieving high-quality stitching and prolonging the lifespan of a sewing machine.

-

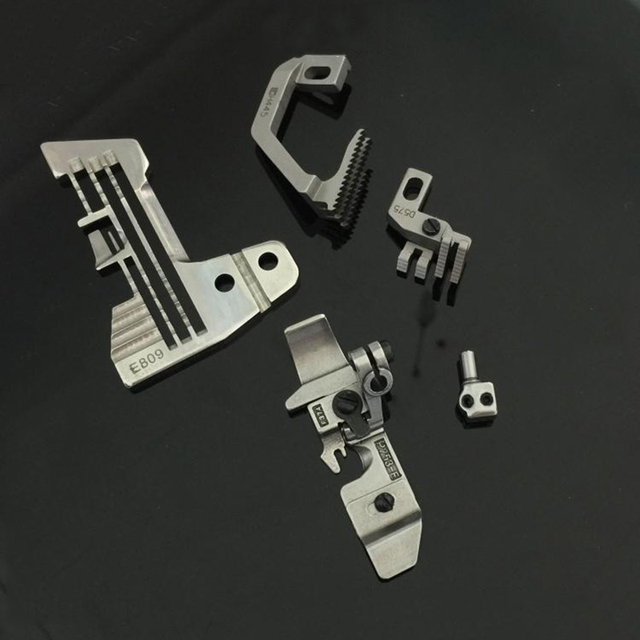

Presser-Foot Assembly

The presser-foot assembly is an essential part of a sewing machine that holds the fabric in place and ensures that it is fed smoothly through the machine. This assembly is made up of several spare parts that work together to create a firm grip on the fabric, allowing for precise stitching and preventing the fabric from slipping or bunching up.

-

Pressure Foot Assembly

The Pressure Foot Assembly is a spare part that is a critical component of a sewing machine’s feeding system. It is responsible for holding the fabric in place and controlling the amount of pressure applied to it during the stitching process.

The Pressure Foot Assembly typically consists of a metal or plastic foot that is positioned above the fabric being stitched. It is designed to hold the fabric in place and guide it through the machine at a consistent rate. The Pressure Foot Assembly also typically contains a mechanism for adjusting the amount of pressure applied to the fabric, allowing the user to control the stitching tension.

If the Pressure Foot Assembly becomes worn or damaged, it can cause the fabric to be fed unevenly or not at all, resulting in poor-quality stitching or even needle breakage. In such cases, it may be necessary to replace the Pressure Foot Assembly with a new one.

-

Sewing Machine Belt

Sewing machine spare parts are components that can be replaced to repair or enhance the performance of a sewing machine. Some common spare parts include needles, bobbins, presser feet, thread guides, and belts. Needles come in different sizes and types to accommodate various fabrics and stitching techniques. Bobbins hold the lower thread and can be made of plastic or metal. Presser feet help to hold the fabric in place while sewing and can also be swapped out for different types for specific sewing tasks. Thread guides help to control the flow of thread through the machine, and belts connect the motor to the machine’s moving parts. Other spare parts may include light bulbs, motors, and electronic components. It is important to use the correct spare parts for a particular sewing machine model to ensure proper functioning and avoid damage.

-

Sewing machine spare parts

Sewing machine spare parts are components that can be replaced to repair or enhance the performance of a sewing machine. Some common spare parts include needles, bobbins, presser feet, thread guides, and belts. Needles come in different sizes and types to accommodate various fabrics and stitching techniques. Bobbins hold the lower thread and can be made of plastic or metal. Presser feet help to hold the fabric in place while sewing and can also be swapped out for different types for specific sewing tasks. Thread guides help to control the flow of thread through the machine, and belts connect the motor to the machine’s moving parts. Other spare parts may include light bulbs, motors, and electronic components. It is important to use the correct spare parts for a particular sewing machine model to ensure proper functioning and avoid damage.

-

Sewing machine spare parts

Sewing machine spare parts are components that can be replaced to repair or enhance the performance of a sewing machine. Some common spare parts include needles, bobbins, presser feet, thread guides, and belts. Needles come in different sizes and types to accommodate various fabrics and stitching techniques. Bobbins hold the lower thread and can be made of plastic or metal. Presser feet help to hold the fabric in place while sewing and can also be swapped out for different types for specific sewing tasks. Thread guides help to control the flow of thread through the machine, and belts connect the motor to the machine’s moving parts. Other spare parts may include light bulbs, motors, and electronic components. It is important to use the correct spare parts for a particular sewing machine model to ensure proper functioning and avoid damage.

-

Sewing machine spare parts

Sewing machine spare parts are components that can be replaced to repair or enhance the performance of a sewing machine. Some common spare parts include needles, bobbins, presser feet, thread guides, and belts. Needles come in different sizes and types to accommodate various fabrics and stitching techniques. Bobbins hold the lower thread and can be made of plastic or metal. Presser feet help to hold the fabric in place while sewing and can also be swapped out for different types for specific sewing tasks. Thread guides help to control the flow of thread through the machine, and belts connect the motor to the machine’s moving parts. Other spare parts may include light bulbs, motors, and electronic components. It is important to use the correct spare parts for a particular sewing machine model to ensure proper functioning and avoid damage.

-

Sewing machine spare parts

Sewing machine spare parts are components that can be replaced to repair or enhance the performance of a sewing machine. Some common spare parts include needles, bobbins, presser feet, thread guides, and belts. Needles come in different sizes and types to accommodate various fabrics and stitching techniques. Bobbins hold the lower thread and can be made of plastic or metal. Presser feet help to hold the fabric in place while sewing and can also be swapped out for different types for specific sewing tasks. Thread guides help to control the flow of thread through the machine, and belts connect the motor to the machine’s moving parts. Other spare parts may include light bulbs, motors, and electronic components. It is important to use the correct spare parts for a particular sewing machine model to ensure proper functioning and avoid damage.

-

Sewing machine spare parts

Sewing machine spare parts are components that can be replaced to repair or enhance the performance of a sewing machine. Some common spare parts include needles, bobbins, presser feet, thread guides, and belts. Needles come in different sizes and types to accommodate various fabrics and stitching techniques. Bobbins hold the lower thread and can be made of plastic or metal. Presser feet help to hold the fabric in place while sewing and can also be swapped out for different types for specific sewing tasks. Thread guides help to control the flow of thread through the machine, and belts connect the motor to the machine’s moving parts. Other spare parts may include light bulbs, motors, and electronic components. It is important to use the correct spare parts for a particular sewing machine model to ensure proper functioning and avoid damage.

-

Sewing machine spare parts

Sewing machine spare parts are components that can be replaced to repair or enhance the performance of a sewing machine. Some common spare parts include needles, bobbins, presser feet, thread guides, and belts. Needles come in different sizes and types to accommodate various fabrics and stitching techniques. Bobbins hold the lower thread and can be made of plastic or metal. Presser feet help to hold the fabric in place while sewing and can also be swapped out for different types for specific sewing tasks. Thread guides help to control the flow of thread through the machine, and belts connect the motor to the machine’s moving parts. Other spare parts may include light bulbs, motors, and electronic components. It is important to use the correct spare parts for a particular sewing machine model to ensure proper functioning and avoid damage.

-

Sewing machine spare parts

Sewing machine spare parts are components that can be replaced to repair or enhance the performance of a sewing machine. Some common spare parts include needles, bobbins, presser feet, thread guides, and belts. Needles come in different sizes and types to accommodate various fabrics and stitching techniques. Bobbins hold the lower thread and can be made of plastic or metal. Presser feet help to hold the fabric in place while sewing and can also be swapped out for different types for specific sewing tasks. Thread guides help to control the flow of thread through the machine, and belts connect the motor to the machine’s moving parts. Other spare parts may include light bulbs, motors, and electronic components. It is important to use the correct spare parts for a particular sewing machine model to ensure proper functioning and avoid damage.

-

Sewing machine spare parts

Sewing machine spare parts are components that can be replaced to repair or enhance the performance of a sewing machine. Some common spare parts include needles, bobbins, presser feet, thread guides, and belts. Needles come in different sizes and types to accommodate various fabrics and stitching techniques. Bobbins hold the lower thread and can be made of plastic or metal. Presser feet help to hold the fabric in place while sewing and can also be swapped out for different types for specific sewing tasks. Thread guides help to control the flow of thread through the machine, and belts connect the motor to the machine’s moving parts. Other spare parts may include light bulbs, motors, and electronic components. It is important to use the correct spare parts for a particular sewing machine model to ensure proper functioning and avoid damage.

-

Sewing machine spare parts

Sewing machine spare parts are components that can be replaced to repair or enhance the performance of a sewing machine. Some common spare parts include needles, bobbins, presser feet, thread guides, and belts. Needles come in different sizes and types to accommodate various fabrics and stitching techniques. Bobbins hold the lower thread and can be made of plastic or metal. Presser feet help to hold the fabric in place while sewing and can also be swapped out for different types for specific sewing tasks. Thread guides help to control the flow of thread through the machine, and belts connect the motor to the machine’s moving parts. Other spare parts may include light bulbs, motors, and electronic components. It is important to use the correct spare parts for a particular sewing machine model to ensure proper functioning and avoid damage.

-

Sewing machine spare parts

Sewing machine spare parts are components that can be replaced to repair or enhance the performance of a sewing machine. Some common spare parts include needles, bobbins, presser feet, thread guides, and belts. Needles come in different sizes and types to accommodate various fabrics and stitching techniques. Bobbins hold the lower thread and can be made of plastic or metal. Presser feet help to hold the fabric in place while sewing and can also be swapped out for different types for specific sewing tasks. Thread guides help to control the flow of thread through the machine, and belts connect the motor to the machine’s moving parts. Other spare parts may include light bulbs, motors, and electronic components. It is important to use the correct spare parts for a particular sewing machine model to ensure proper functioning and avoid damage.

-

Sewing machine spare parts

Sewing machine spare parts are components that can be replaced to repair or enhance the performance of a sewing machine. Some common spare parts include needles, bobbins, presser feet, thread guides, and belts. Needles come in different sizes and types to accommodate various fabrics and stitching techniques. Bobbins hold the lower thread and can be made of plastic or metal. Presser feet help to hold the fabric in place while sewing and can also be swapped out for different types for specific sewing tasks. Thread guides help to control the flow of thread through the machine, and belts connect the motor to the machine’s moving parts. Other spare parts may include light bulbs, motors, and electronic components. It is important to use the correct spare parts for a particular sewing machine model to ensure proper functioning and avoid damage.

-

Sewing machine spare parts

Sewing machine spare parts are components that can be replaced to repair or enhance the performance of a sewing machine. Some common spare parts include needles, bobbins, presser feet, thread guides, and belts. Needles come in different sizes and types to accommodate various fabrics and stitching techniques. Bobbins hold the lower thread and can be made of plastic or metal. Presser feet help to hold the fabric in place while sewing and can also be swapped out for different types for specific sewing tasks. Thread guides help to control the flow of thread through the machine, and belts connect the motor to the machine’s moving parts. Other spare parts may include light bulbs, motors, and electronic components. It is important to use the correct spare parts for a particular sewing machine model to ensure proper functioning and avoid damage.

-

Siruba 747 Looper Upper and Lower

The Siruba 747 Looper Upper and Lower are spare parts that are critical components of a serger or overlock sewing machine’s loopers mechanism. They are responsible for creating the loops that encase the raw edges of fabric and prevent them from fraying.

The Looper Upper and Lower typically consist of two metal pieces that are positioned above and below the fabric being stitched. They work in tandem to form the loop and secure it in place. The Looper Upper and Lower move in a synchronized motion, threading the thread through the fabric and forming the stitch.

If the Looper Upper and Lower become worn or damaged, they can cause the machine to produce poor-quality stitching or even break the needles. In such cases, it may be necessary to replace the Looper Upper and Lower with new ones.

-

Siruba 747-4-4 Needle

The Siruba 747-4-4 Needle Holder is a spare part that is a critical component of a serger or overlock sewing machine’s needle mechanism. It is responsible for holding the needles in place and controlling their movement during the stitching process.

The Needle Holder typically consists of a metal or plastic bracket that holds the needles securely in place. It is designed to guide the needles through the fabric at a consistent rate and prevent them from bending or breaking. The Needle Holder also typically contains a mechanism for adjusting the needle position, allowing the user to control the stitching tension.

If the Needle Holder becomes worn or damaged, it can cause the needles to be misaligned or fall out of the machine, resulting in poor-quality stitching or even machine damage. In such cases, it may be necessary to replace the Needle Holder with a new one.